LASER HARDENING

After the desired temperature is obtained, the laser travels a pre-determined path along the component.

As the laser travels, the base material acts as a heat sink, quickly quenching the heated surface. The quick cooling provides a very fine martensitic grain structure, creating a superior localized heat treatment.

Advantages

With laser precision and robotic control, laser hardening can be applied to complex surfaces while achieving repeatable hardness and case depth.

The surface finish after laser hardening is excellent and, in some cases, requires no finishing work.

The process is used exclusively on ferrous materials containing a minimum of 0.20 percent carbon.

Benefits

Hardening of selected regions with pinpoint accuracy

Very fast and efficient

Depending on carbon/alloy content, some steels can be hardened to more than 62 HRC

Automated temperature control for consistent case depth and hardness

Minimal, if any, part distortion

Improves wear characteristics without changing the part dimensionally

Applications

Locating pins

Hoist drum grooves

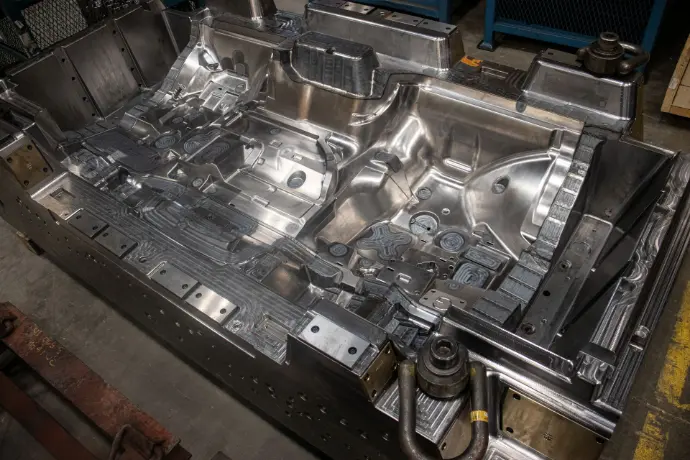

Metal forming dies

Gear teeth

Cam channels

Crane wheels

Down-hole drilling components

Plastic injection tooling parting lines

Metal and fabric trim dies

Core box blow tube abrasion