METALLURGICAL LAB

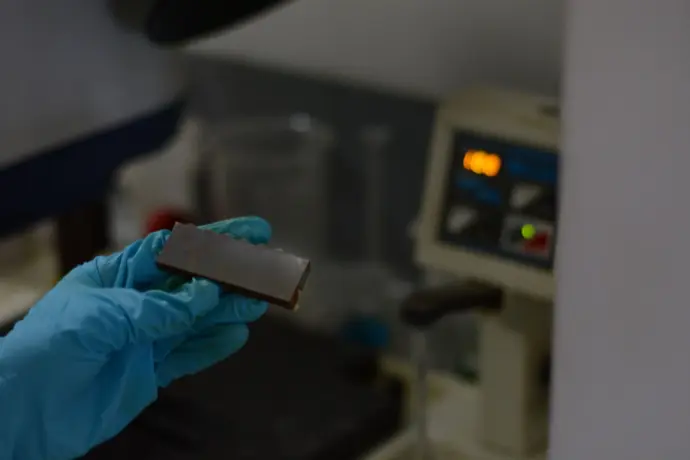

Our state-of-the-art metallurgical lab helps us ensure that our coating materials are precisely what your parts need in the field.

Our expert lab team uses advanced testing and metallurgical techniques to ensure your equipment performs at its best. Trust us to deliver durable, cost-effective solutions tailored to your most demanding industrial needs.

Our laboratory serves to continually develop and improve manufacturing process parameters for all of Fusion Industrial Laser's additive services.

We also provide assistance to customers in need of metallurgical testing or third-party analysis.

Fusion Industrial Laser metallurgical lab services include:

Analysis of welds

Analysis of coatings

Customized coatings

Reverse engineering

Capabilities

Metallographic Preparation

Wire EDM

Leco mounting press

Buehler grinder polisher

SEM/EDS Capabilities

Access to state-of-the-art scanning electron microscope and energy-dispersive spectroscopy

Chemical Analysis

SPECTRO optical emission handheld spectrometer

Hardness

Portable ultrasonic hardness tester

Portable Leeb hardness tester

Struers Vickers microhardness tester

200g, 300g, 500g, 1kg

Case depth measurements

Metallography

Handheld microscope

Nikon metallographic microscope

50x to 400x

Clemex vision Captiva software

Case depth measurements

Mechanical Testing Capabilities

Tensile testing

Charpy V-notch testing

Abrasive wear testing

Polmer Analysis Capabilities

Access to GC-MS, FTIR, DSC, and TGA testing

Surface Roughness Testing

Mitutoyo Profilometere